Introduction

Ultraviolet (UV) disinfection equipment has become a cornerstone in maintaining hygiene and safety across a range of industries. UV light, particularly in the germicidal range (200-280 nm), is highly effective in deactivating the DNA and RNA of bacteria, viruses, and other pathogens, rendering them incapable of replication and infection. As industries increasingly prioritize cleanliness and contamination control, UV disinfection systems offer a chemical-free, efficient solution. This guide explores the applications of UV disinfection equipment in various industries, highlighting its benefits, mechanisms, and diverse use cases.

Definition

The technology known as ultraviolet (UV) disinfection equipment employs ultraviolet radiation to kill or inactivate bacteria, viruses, and protozoa. These creatures’ DNA and RNA are harmed by UV radiation, which stops them from procreating and spreading diseases. In order to eliminate dangerous bacteria without the use of chemicals, UV disinfection is frequently utilized in surface disinfection applications, air purification systems, and water treatment systems.

How UV Disinfection Works

UV disinfection relies on ultraviolet-C (UV-C) light, a specific wavelength that has germicidal properties. When pathogens are exposed to UV-C light, their genetic material absorbs the energy, causing DNA and RNA damage. This damage prevents replication, effectively neutralizing the pathogen.

There are different types of UV disinfection systems, including:

- Air Disinfection Systems – These systems are used to disinfect air in enclosed spaces.

- Water Disinfection Systems – Primarily used in treating drinking water, wastewater, and industrial water processes.

- Surface Disinfection Systems – Used for sterilizing high-contact surfaces, medical equipment, and industrial machinery.

1. Healthcare and Medical Facilities

One of the most significant applications of UV disinfection is in healthcare settings. Hospitals, clinics, and other medical facilities are breeding grounds for pathogens due to the constant influx of sick patients. Nosocomial (hospital-acquired) infections are a serious concern, making disinfection a critical task.

Applications in Healthcare:

- Air Disinfection: Airborne pathogens can spread rapidly in medical environments. UV air purification systems are often integrated into HVAC systems to ensure clean, germ-free air circulation in patient rooms, operating theaters, and intensive care units (ICUs).

- Surface Disinfection: High-touch surfaces like doorknobs, bedrails, and medical equipment are frequent contamination points. Portable UV disinfection devices and stationary units can efficiently sterilize these surfaces between uses, reducing the risk of cross-contamination.

- Medical Equipment Sterilization: UV light is used in conjunction with traditional methods to sterilize sensitive medical devices that cannot be exposed to heat or chemicals.

Benefits: UV disinfection reduces the reliance on harsh chemical disinfectants, minimizes the risk of chemical exposure for staff, and enhances infection control measures.

2. Water Treatment

The water treatment industry was one of the earliest adopters of UV disinfection technology. UV systems treat drinking water, wastewater, and process water in industries. The ability of UV light to neutralize pathogens without adding chemicals makes it particularly useful in ensuring safe water supplies.

Applications in Water Treatment:

- Drinking Water Disinfection: UV systems in municipal water treatment plants disinfect water without altering its taste or chemical composition. This makes it an eco-friendly alternative to chlorine-based disinfection methods.

- Wastewater Treatment: In wastewater treatment plants, UV technology ensures that treated water released into the environment is free from harmful pathogens. UV disinfection is especially critical for communities near natural water bodies where pathogen contamination could pose a risk to public health.

- Aquaculture and Fish Farming: Clean water is essential for maintaining the health of aquatic organisms in fish farms and aquaculture systems. UV systems help prevent disease outbreaks by keeping water pathogen-free without using harmful chemicals that could affect fish health.

Benefits: UV disinfection in water treatment eliminates the need for chemical disinfectants like chlorine, reducing environmental and human health risks.

3. Food and Beverage Industry

Maintaining high hygiene standards is crucial in the food and beverage industry to prevent foodborne illnesses. UV disinfection technology has become an invaluable tool for sterilizing food processing environments and equipment.

Applications in the Food Industry:

- Surface Disinfection: UV systems can disinfect conveyor belts, packaging equipment, and other surfaces that come into direct contact with food in food processing facilities by installing them. This reduces the risk of cross-contamination between different batches of food products.

- Air Disinfection: In food processing plants, maintaining clean air is essential to prevent airborne contaminants from settling on food products. UV-C air purifiers can disinfect the air in production areas, storage rooms, and packaging facilities.

- Water Disinfection: Many food and beverage companies use UV technology to disinfect process water used in washing fruits, vegetables, and other raw materials. UV-treated water can also power the production of beverages such as bottled water and soft drinks.

Benefits: UV disinfection in the food industry enhances product safety, extends shelf life, and reduces the reliance on chemical preservatives.

4. Pharmaceutical Industry

The pharmaceutical industry requires stringent hygiene and contamination control to ensure the safety and efficacy of products. UV disinfection equipment plays a pivotal role in maintaining clean manufacturing environments and preventing microbial contamination.

Applications in Pharmaceuticals:

- Surface and Equipment Sterilization: UV systems disinfect surfaces, packaging materials, and manufacturing equipment to ensure that products, such as sterile injectables and other sensitive medications, remain uncontaminated during production.

- Air and Water Purification: Clean air and water are essential for pharmaceutical manufacturing. UV disinfection systems can purify air in cleanrooms and treat process water to eliminate any microbial contaminants that could compromise product safety.

Benefits: UV disinfection provides a non-invasive, chemical-free way to maintain the ultra-clean environments required for pharmaceutical production.

5. Hospitality Industry

Hotels, restaurants, and other hospitality venues are increasingly using UV disinfection to maintain high levels of cleanliness, especially in response to the COVID-19 pandemic.

Applications in Hospitality:

- Room and Surface Disinfection: Hotels use UV-C devices to disinfect guest rooms, including bedding, furniture, and high-touch surfaces. In restaurants, UV systems are used to sterilize kitchen surfaces, dining tables, and utensils.

- Air Purification: UV air purifiers installed in HVAC systems disinfect circulating air, reduce the spread of airborne pathogens in common areas like hotel lobbies, conference rooms, and dining halls.

- Spa and Pool Water Treatment: UV disinfection systems in hotel spas and swimming pools ensure clean, pathogen-free water without the need for high levels of chlorine.

Benefits: UV disinfection enhances guest safety by ensuring a high level of cleanliness, boosting customer confidence in hospitality services.

6. Manufacturing and Industrial Applications

In manufacturing plants, maintaining contamination-free environments is essential for ensuring the quality of products and the safety of workers.

Applications in Manufacturing:

- Surface and Equipment Disinfection: UV systems disinfect assembly lines, machinery, and packaging materials. This is particularly important in industries like electronics and pharmaceuticals, where even minor contamination can affect product quality.

- Air Disinfection in Cleanrooms: Manufacturing environments often require cleanroom conditions to prevent dust, microbes, and other contaminants from entering the production process. UV air disinfection systems help maintain sterile air in these environments.

Benefits: UV disinfection enhances product quality control, reduces the risk of contamination, and improves worker safety by reducing the presence of pathogens.

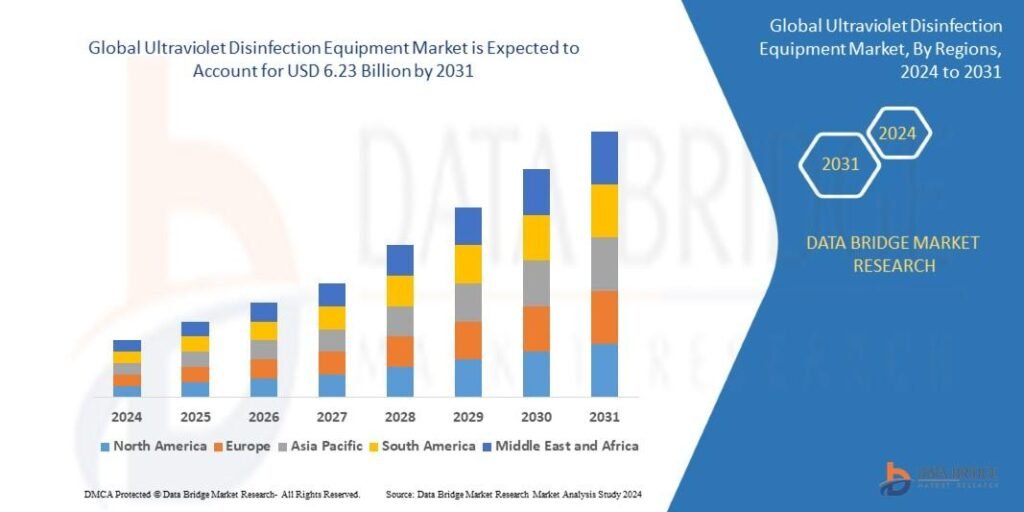

Growth Rate of Ultraviolet Disinfection Equipment

The size of the global market for ultraviolet disinfection equipment was estimated at USD 2.19 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 13.95% from 2024 to 2031, reaching USD 6.23 billion.

Conclusion

UV disinfection equipment has proven to be a versatile and effective solution across various industries. From healthcare and food processing to water treatment and hospitality, UV technology provides a chemical-free, eco-friendly way to maintain high hygiene standards and ensure the safety of products, environments, and people. As industries continue to prioritize cleanliness and infection control, UV disinfection systems will undoubtedly play an increasingly important role in shaping safer and healthier workplaces.

More Stories

Washing Machine Maintenance in Riyadh

Best LG Washing Machines Repair in Jeddah

Exploring the Role of Medical AI Chatbots in Enhancing Patient Feedback Systems